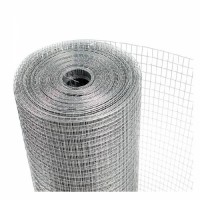

Punching Hole Mesh Manufacturer & Stainless Steel Hole Mesh Supplier

As a professional punching hole mesh manufacturer, Yadong Wire Mesh specializes in the production of high-precision perforated punching hole mesh for industrial, architectural, filtration, and decorative applications. With advanced CNC punching technology, strict quality control, and large-scale production capacity, we provide custom stainless steel hole mesh solutions to global distributors, contractors, wholesalers, and industrial buyers.

We are a trusted stainless steel hole mesh supplier, offering premium-grade SS304 and SS316 perforated metal sheets, carbon steel punching mesh, galvanized steel perforated sheets, and aluminum hole mesh. Our factory supports custom hole patterns, precise tolerances, bulk production, and fast export delivery, making us a reliable global supplier for OEM and project-based orders.

What is Punching Hole Mesh?

Punching hole mesh, also known as perforated metal mesh, is manufactured by mechanically punching uniform holes into metal sheets using high-speed CNC punching machines. This creates precise hole patterns that provide ventilation, filtration, acoustic control, weight reduction, and decorative appeal, while maintaining high structural strength.

As a leading punching hole mesh manufacturer, we produce metal perforated sheets in multiple materials, thickness ranges, and hole patterns to meet the diverse needs of industrial processing, construction, machinery protection, and architectural design.

Stainless Steel Hole Mesh Supplier – SS304 & SS316 Perforated Sheets

As an experienced stainless steel hole mesh supplier, we specialize in producing high-quality SS304 and SS316 perforated punching hole mesh, offering excellent corrosion resistance, strength, hygiene safety, and durability.

Key Advantages of Stainless Steel Punching Hole Mesh:

- Excellent corrosion and rust resistance

- High mechanical strength and durability

- Hygienic surface for food and pharmaceutical industries

- Excellent heat and chemical resistance

- Long service life in outdoor and harsh environments

Common Stainless Steel Grades:

- SS304 Punching Hole Mesh – Food processing, filtration, ventilation, decorative panels

- SS316 Punching Hole Mesh – Marine, chemical plants, pharmaceutical, offshore structures

We support custom perforation patterns, sheet sizes, thicknesses, and finishing options, making us a professional stainless steel hole mesh supplier for industrial-grade projects worldwide.

Materials Available

We manufacture punching hole mesh using a wide range of premium raw materials:

- Stainless Steel (SS304, SS316)

- Carbon Steel

- Galvanized Steel (GI)

- Aluminum Sheet

- Copper & Brass (on request)

Technical Specifications of Punching Hole Mesh

|

Parameter |

Specification |

|

Material |

SS304, SS316, Carbon Steel, Galvanized Steel, Aluminum |

|

Sheet Thickness |

0.3mm – 12mm |

|

Hole Diameter |

0.5mm – 100mm |

|

Sheet Size |

1×2m, 1.22×2.44m, Custom |

|

Hole Pattern |

Round, Square, Slot, Hexagonal, Decorative |

|

Surface Finish |

Polished, Brushed, Powder Coated, Galvanized |

|

Tolerance |

±0.05mm |

Punching Hole Patterns We Offer

As a professional punching hole mesh manufacturer, we produce a wide variety of perforation patterns:

- Round Hole Mesh

- Square Hole Mesh

- Slotted Hole Mesh

- Hexagonal Hole Mesh

- Decorative Perforated Panels

- Custom Pattern Punching

Manufacturing Process & Quality Control

Our punching hole mesh manufacturing process ensures high precision, consistent quality, and large-scale production efficiency.

Production Process:

- Raw material inspection

- CNC punching and perforation

- Edge trimming and flattening

- Surface treatment

- Quality inspection

- Packaging and export packing

Quality Control:

- Raw material testing

- Hole diameter measurement

- Flatness inspection

- Surface finish check

- Dimensional accuracy control

Our strict quality control ensures uniform hole distribution, precise tolerances, smooth edges, and consistent sheet flatness.

Applications of Punching Hole Mesh

Our punching hole mesh is widely used across various industries:

Industrial Applications

- Filtration and screening

- Machinery safety guards

- Equipment ventilation

- Conveyor belts

- Grain and food processing sieves

Architectural & Decorative Applications

- Building facades

- Interior decorative panels

- Ceiling panels

- Stair railings

- Sunshade panels

Environmental & Acoustic Applications

- Sound insulation panels

- Noise barriers

- Air ventilation panels

- Dust filtration systems

Why Choose Yadong as Your Punching Hole Mesh Manufacturer?

- 15+ years manufacturing experience

- Advanced CNC punching equipment

- Strict quality management system

- Wide material & thickness range

- Strong custom production capability

- Fast bulk order delivery

- Global export experience

- Competitive factory-direct pricing

Custom Punching Hole Mesh Solutions

We provide OEM and ODM services for global buyers, offering:

- Custom hole diameter & pattern

- Special sheet sizes

- Logo punching

- Surface coating solutions

- Special material requirements

Whether you need prototype samples or bulk industrial orders, we deliver high-quality solutions tailored to your exact specifications.

Packaging & Global Delivery

We use standard export wooden pallets, waterproof packaging, and reinforced edge protection to ensure damage-free shipping. Our punching hole mesh products are exported to:

- USA

- Europe

- Middle East

- Southeast Asia

- Australia

- Africa